PU timing belts are manufactured with thermoplastic polyurethane having excellent wear resistance and high tensile Steel (Or Aramid) cords as tension member. Both high quality materials combined form the basis for dimensionally stable and high resistance polyurethane timing belts. Polyurethane timing belts have a very high span rigidity

Features

- Excellent dimensional Stability

- High Abrasion resistance

- High resistance to most oils and grease

- High Resistance to Hydrolysis, Ozone, etc.

- Low Noise

- Low Maintenance

- Permits large centre distance

PU timing belts are available in Endless, Open or as Welded Endless and are widely used for power transmission, Conveying & Linear drive applications.

Standard PU timing Belt range:

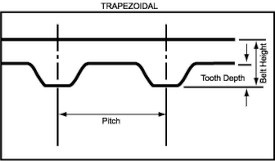

| Belt Code | Pitch (mm) | Tooth Depth (mm) | Belt Height (mm) |

|---|---|---|---|

| T2.5 | 2.5 | 0.7 | 1.3 |

| T5 | 5 | 1.2 | 2.2 |

| T10 | 10 | 2.5 | 4.5 |

| T20 | 20 | 5.0 | 8.0 |

| AT5 | 5 | 1.2 | 2.7 |

| AT10 | 10 | 2.5 | 4.5 |

| AT20 | 20 | 5.0 | 8.0 |

PU timing belts are available as Flex or truly Endless, Jointed or Welded Endless and in Open lengths.

Special Series Timing Belts

To meet the requirements of todays design engineers polyurethane belts are available in several special pitches and designs like:

- High Performance ATP, ATL series

- Self Guiding BAT, SFAT, ATK, TK Series

- ATN System, etc.

Address: A-9, New Sonal Industrial Estate, Saki Vihar Road, Mumbai - 400 072, Maharashtra, India

Address: A-9, New Sonal Industrial Estate, Saki Vihar Road, Mumbai - 400 072, Maharashtra, India  Phone:

Phone:  Email:

Email: